Fillet Weld Design Methods: Enhancing Joint Efficiency and Appearance for Structural Stability

In the world of architectural engineering and manufacture, the significance of fillet weld style approaches can not be overemphasized. By thoroughly thinking about variables such as weld account optimization, material choice, joint preparation strategies, welding procedure efficiency, and visual improvement approaches, designers and producers can achieve a harmonious balance in between functionality and look in their bonded frameworks.

Weld Profile Optimization

Accomplishing an ideal weld account entails a meticulous consideration of factors such as material thickness, joint configuration, welding setting, and wanted welding speed. In addition, the option of proper welding criteria, such as voltage, present, and take a trip rate, is basic in controlling the shape and dimensions of the fillet weld. Making use of sophisticated welding methods, such as pulse welding or robot welding, can better improve the weld profile to fulfill specific design requirements and top quality requirements.

In significance, weld profile optimization is a basic element of fillet weld design that directly affects the total performance and dependability of welded joints in structural applications.

Material Selection Factors To Consider

When considering material option for fillet weld style, the compatibility of the base metals is a critical element affecting the architectural honesty of the joint. It is necessary to choose materials that not only bonded with each other successfully but likewise possess comparable mechanical homes to make sure the lots is uniformly distributed in between the base and the weld metals. Welding materials with greatly different properties can result in concerns such as anxiety focus, premature joint failing, or breaking.

Additionally, the atmosphere in which the welded framework will certainly run have to be taken into account when selecting materials. Factors like deterioration resistance, temperature level changes, and direct exposure to chemicals can all affect the durability and efficiency of the weld joint. By picking products that appropriate for the designated application and atmosphere, the overall durability and reliability of the welded joint can be substantially boosted.

For that reason, thorough factor to consider of material compatibility and ecological factors is critical in making certain the weld joint's strength, durability, and general structural stability.

Joint Prep Work Strategies

Taking into consideration the critical duty product selection plays in making certain the structural honesty of fillet weld joints, it is crucial to apply accurate joint preparation methods that maximize the link between the base metals. Joint preparation is a crucial step that directly influences the high quality and stamina of the weld.

Additionally, tack welding the components in area prior to the last weld assists preserve positioning and decreases distortion throughout the welding procedure. By carefully following these joint prep work techniques, welders can enhance the overall performance and appearances of fillet weld joints while making certain structural soundness.

Welding Process Effectiveness

Efficient welding procedures are crucial for accomplishing optimal performance and high quality in fillet weld manufacture. One essential element of enhancing welding process effectiveness is selecting the ideal welding method. Aspects such as material kind, joint layout, and welding position need to be very carefully thought about to figure out the most ideal method. Processes like gas steel arc welding (GMAW) and flux-cored arc welding (FCAW) are frequently used for fillet welds due to their adaptability and speed.

Moreover, making sure proper tools arrangement and maintenance is crucial for Learn More effective welding. Regular calibration of welding equipments, inspection of consumables, and maintenance of welding lanterns can avoid downtime and remodel, ultimately conserving time and sources. In addition, employing competent welders with know-how in the certain welding process being used can considerably affect efficiency. Well-trained welders are extra proficient at readjusting criteria, troubleshooting concerns, and maintaining regular weld top quality.

Aesthetic Improvement Techniques

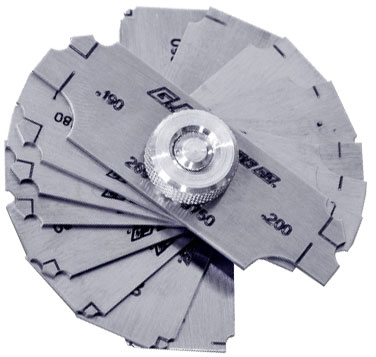

To enhance the top quality of fillet weld fabrication, applying visual enhancement techniques can play a vital function in ensuring precision and accuracy during the welding process. Aesthetic help such as weld dimension assesses and multiplying lenses can help in evaluating weld profiles and measurements precisely. By integrating these aesthetic improvement approaches right into the welding procedure, welders can attain not just structurally sound fillet welds but also aesthetically appealing results that satisfy market standards.

Final Thought

To conclude, optimizing fillet weld layout includes mindful factor to consider of weld account, material selection, joint prep work, welding process efficiency, and visual improvement methods. By applying these techniques, architectural stability can be boosted while additionally attaining visual allure. It is essential to prioritize both efficiency and visual appeals in fillet weld style to make certain the total quality and durability of the important source joint.

By diligently considering elements such as weld account optimization, material option, joint prep work techniques, welding process effectiveness, and visual enhancement designers, approaches and fabricators can achieve an unified equilibrium between capability and appearance in their bonded structures.In the world of fillet weld design, optimizing the weld account plays a crucial role in making sure architectural honesty and efficiency. The weld account, which includes the size use this link and shape of the weld cross-section, straight affects the circulation of stress and anxiety and load-bearing ability within the joint. It is crucial to choose materials that not only bonded with each other successfully yet additionally have similar mechanical homes to guarantee the load is uniformly dispersed in between the base and the weld steels - Gauge Fillet Weld.In final thought, enhancing fillet weld layout entails mindful factor to consider of weld profile, product choice, joint preparation, welding procedure effectiveness, and aesthetic improvement techniques